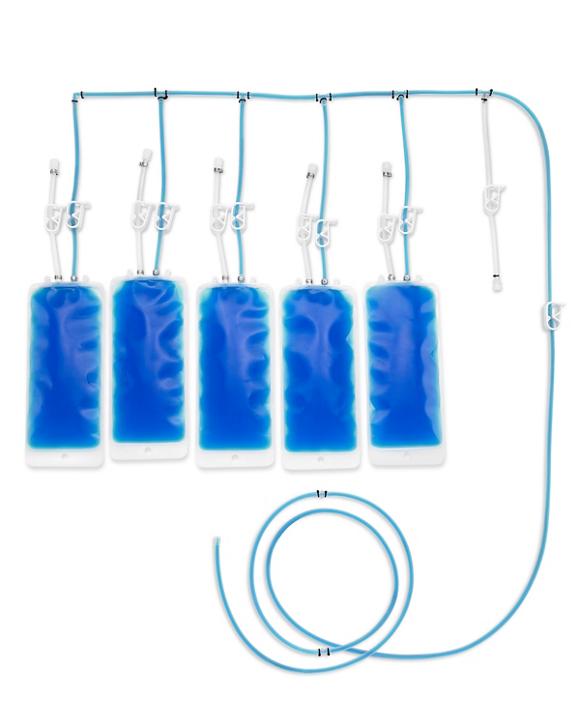

Tube Sets and Manifolds

- Upstream and downstream bioprocessing

- Secure fluid transfer

- Stainless to single use interface

- Aseptic filling and sampling

- Jumpers between non-compatible parts

- High density cell banking

- Bioreactor filtration and support

- Sterile processing and stor

Specifications

Custom Products

We can fabricate unique tube sets and manifolds to your specifications. With decades of experience, we have solutions to help all areas of your process.

Solutions include, but are not limited to:

- Secure fluid transfer

- Stainless-to-single use interface

- Sampling assemblies

- Jumpers between different manufacturer's equipment

- Aseptic filling

- Completely enclosed processing

- Bioreactor filtration and support

- Sterile processing or storage

Tubing Options

We offer a range of biopharmaceutical-grade tubing for disposable bag and bulk solutions designed to meet your fluid handling and transfer needs. Contact Entegris with your requirements and for material options not listed here.

AdvantaFlex® TPE (thermoplastic elastomer) tubing, clear

- Is specifically suited for the pharmaceutical and biopharmaceutical industries

- Meets various ISO and USP standards, including Class VI, and is Animal Drive Component Free (ADCF)

- Excellent for welding and has proven to have a longer pump life than other comparable TPE tubing. Shore A, 50

C-Flex® TPE tubing, clear

- Heat sealable and bondable

- Material composition provides for low protein binding, minimizing potential for active ingredient loss

- Low gas permeability helps maintain pH

- Extremely durable and excels in peristatlic pump applications

- Fully characterized in accordance with USP 24 guidelines

- Formulation 082, Shore A, 60; formulation 050, Shore A, 50; formulation 374 (ADCF), Shore A, 50

C-Flex TPE tubing, opaque

- Heat sealable and bondable

- Low protein binding, minimizing potential for active ingredient loss

- Extremely durable and excels in peristatlic pump applications

- Fully characterized in accordance with USP 24 guidelines

- Formulation 072, Shore A, 60; formulation 050, Shore A, 50

Tygon® silicone tubing

- Platinum cured, silicone tubing has an ultra smooth inner bore to reduce potential for particle entrapment

- Provides the ultimate assurance of purity for sensitive applications

- Fully characterized in accordance with USP 24 and ISO 10993 guidelines

- Shore A, 50

PharMed® tubing

- Specially designed for applications requiring low particulates

- Extremely durable and excels in peristatlic pump applications

- Can be autoclaved repeatedly

- Opaque formula ideal in UV light-sensitive applications

- Fully characterized in accordance with USP and ISO 10993 guidelines

- Shore A, 64

PVC tubing

- Used in many applications where radio frequency (RF) sealing is required

- Meets UPS Class VI requirements

- -41°C to 80°C working temperature

- Handles a variety of chemicals, gases, and liquids

Customization Options

Any tube set or manifold can be packaged together for a specific application. Customized packaging or kitting is also available.

| Sensors | Pressure, temperature, dissolved oxygen, pH |

| Pump elements | Peristaltic, Levitronix, Quattroflow™, etc. |

| Tubing | Silicone, TPE, PVC |

| Connectors | Aseptic, open, Luer |

| Ports | Hose barb, sanitary, threaded |

| Fittings | Sanitary, threaded |

| Bags* | May be constructed from any of our standard films |

| Filters | Vent, sterilizing |

| *Various films are available to ensure compatibility with your cells and liquids. | |

Successfully Opted for software Updates

Tube Sets and Manifolds

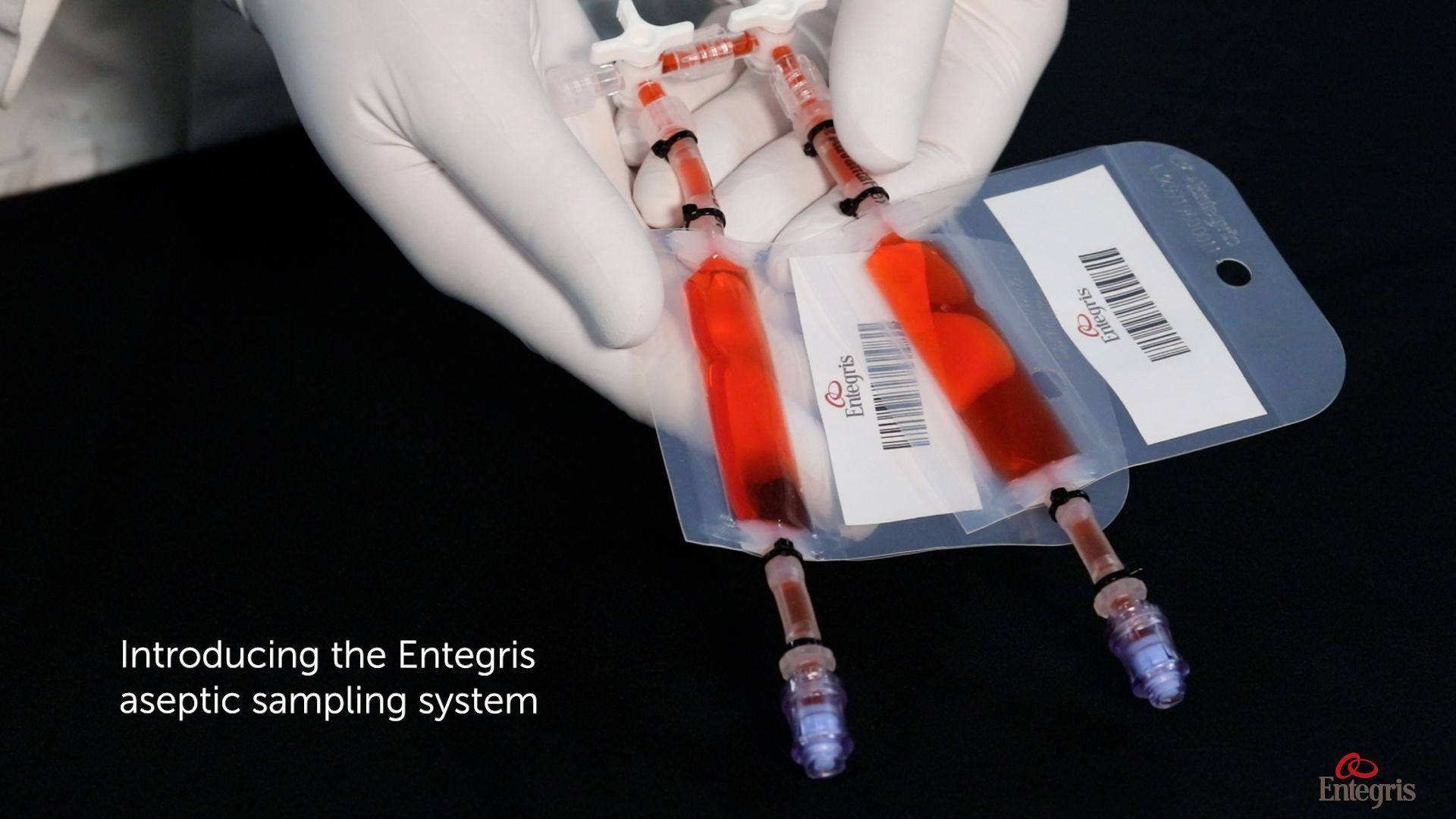

Aramus Aseptic Sampling System

Aramus Aseptic Sampling System User Guide